1970 Super Bee Trunk Pan, Cross Member and More!

The cutting on the ’70 Dodge Super Bee never seems to stop. In removing all of the rotted trunk pan, it was discovered the trunk extensions were either completely gone themselves, or wholly disconnected from the lower quarters, as they too had rotted away.

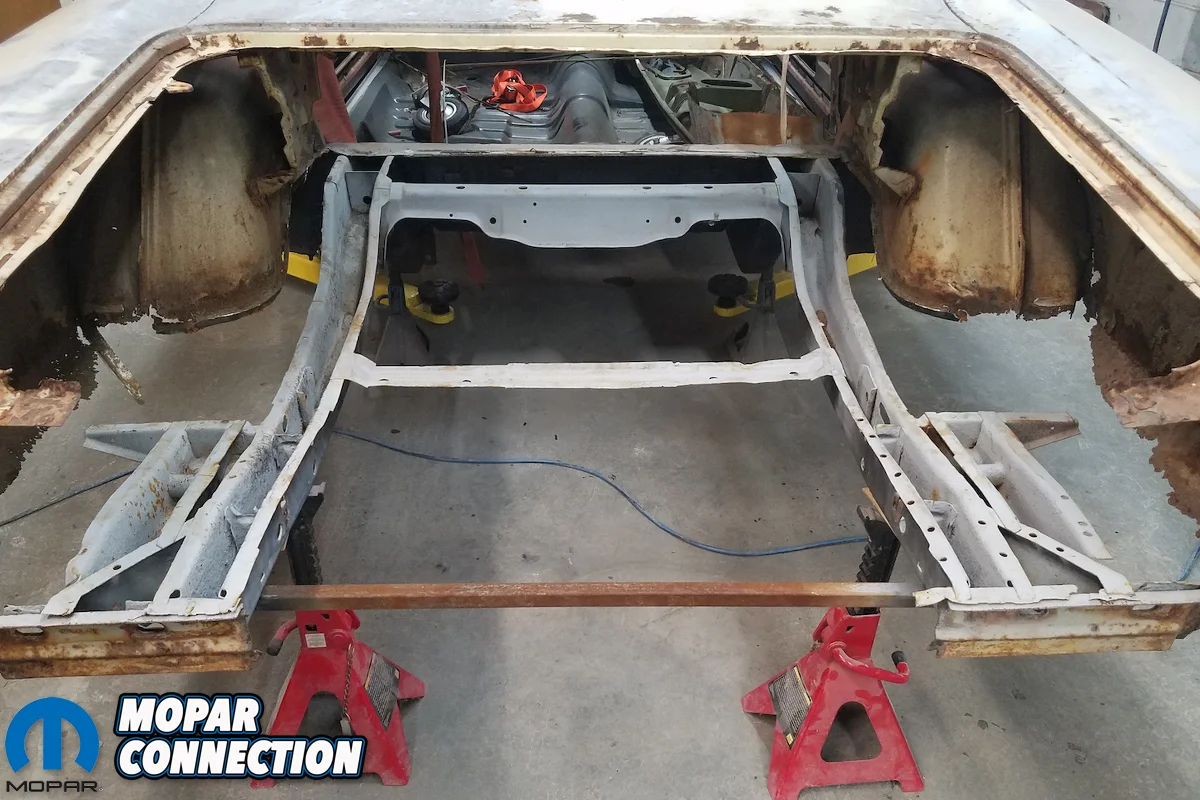

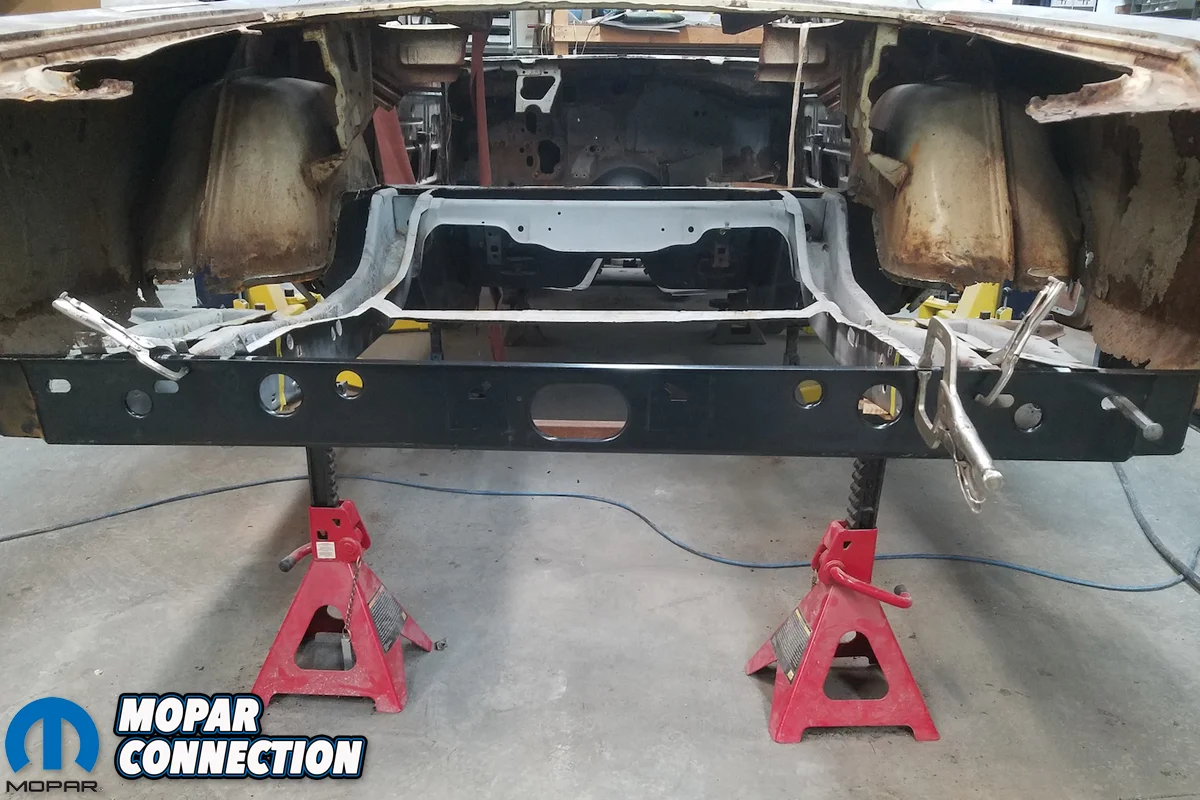

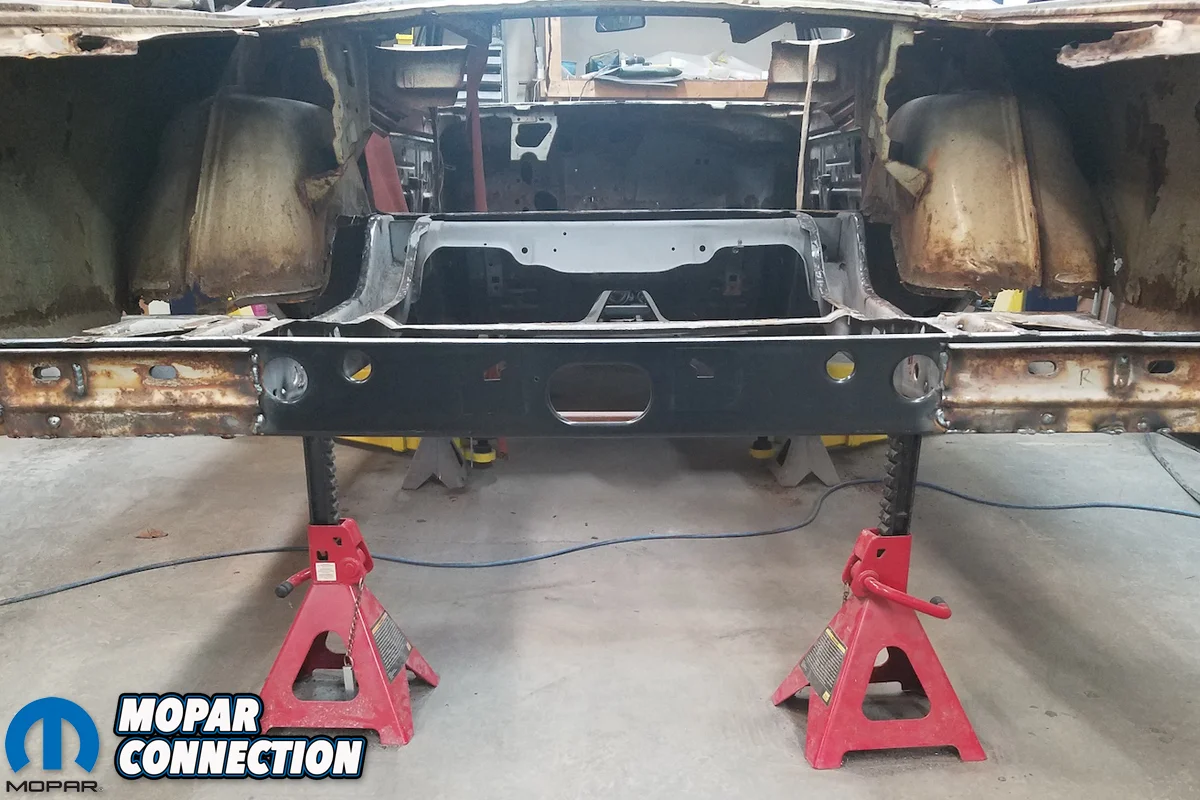

The frame rails appeared to be in decent enough condition, but the rear cross member tying the rails together, as well as the entirety of the rear tail panel was equally gone. Like, you can’t weld anything to it, rice paper-thin gone. So alas, it all had to go. What remained were the loose-hanging remnants of quarter panels, exposed frame rails and little else.

Above: The first step was to set ZomBEE up to take the measurements and match measurements with Dave’s factory-correct ’68 Dodge Coronet 500, being that both B-bodies share the same dimensions. Once all measurements were matched, Dave welded a temporary brace across the frame rails to prevent them from spreading when pan was removed as there was no cross member brace to keep from spreading. The trunk pan is only temporarily placed here in the picture.

David Chamberlain of All Customs Restorations laughed when the car first arrived. “Well, there’s not much left is there?” he joked. Ensuring that the B-body’s frame rails were both straight and level was first, and we documented David’s process earlier. Next, required that we tie the rear frame rails together with a new rear cross member.

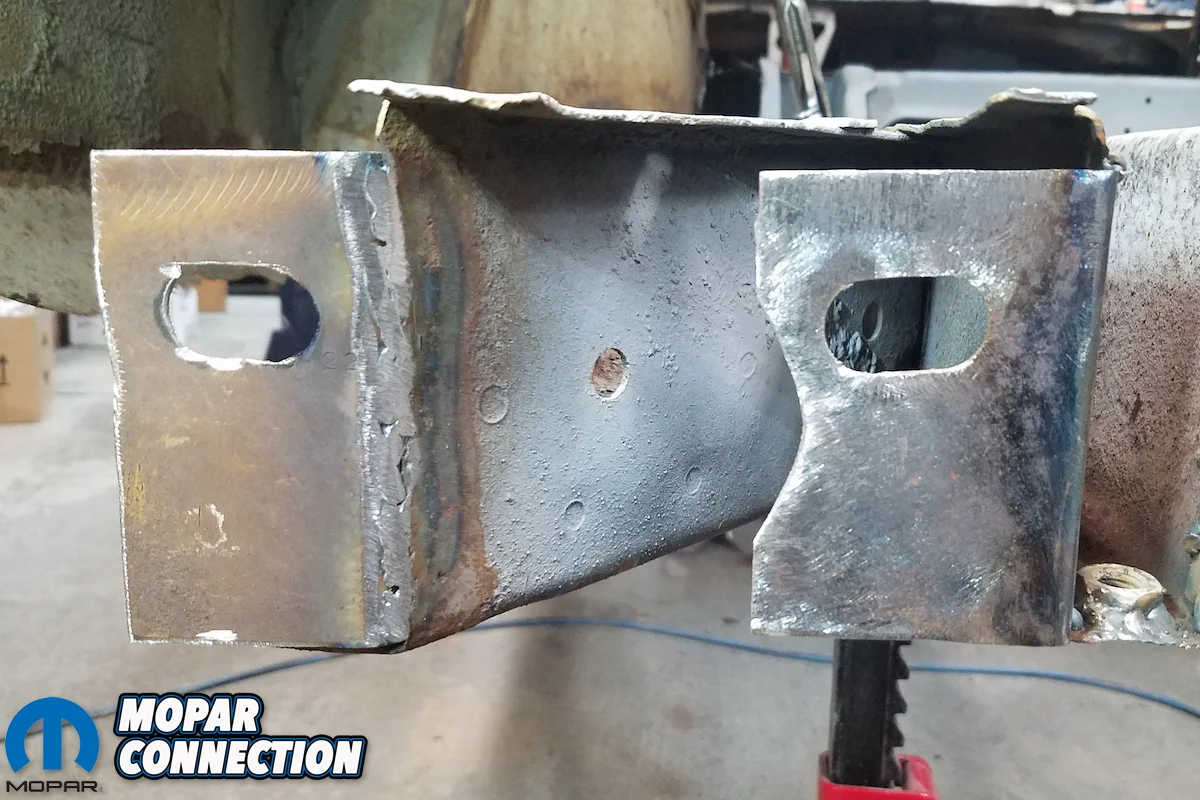

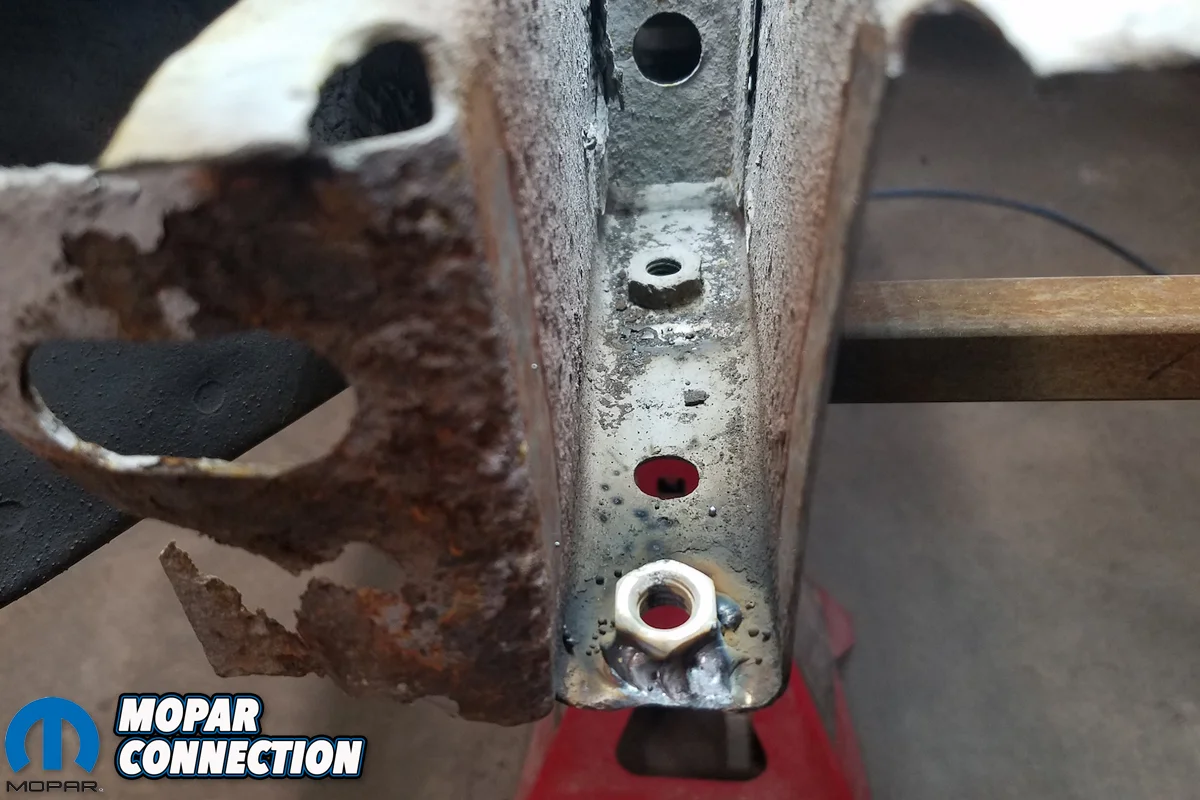

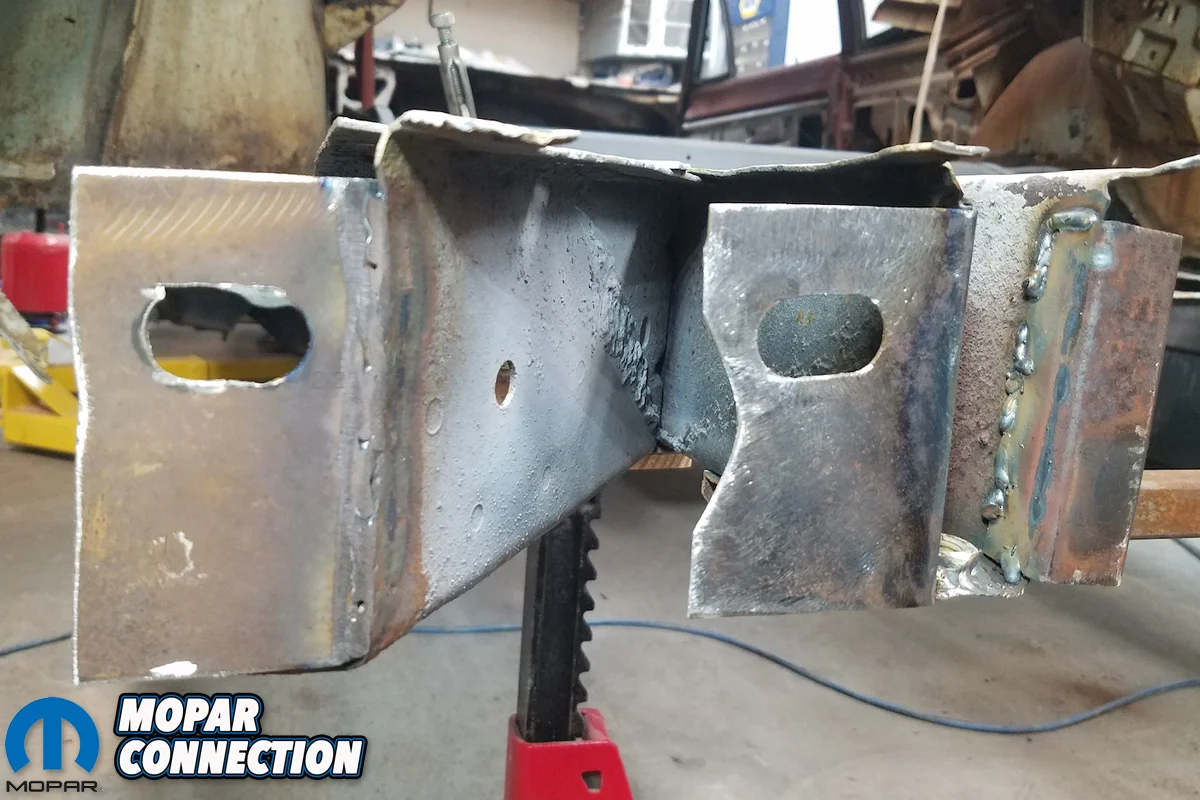

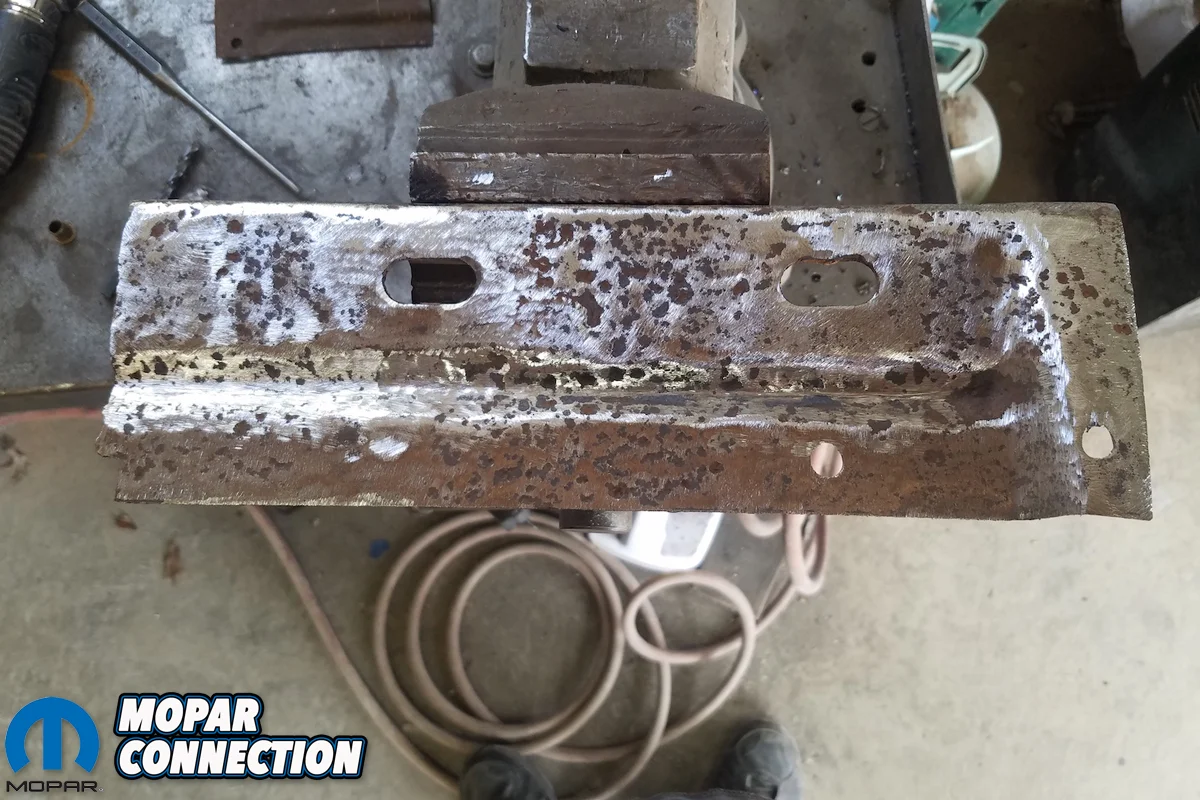

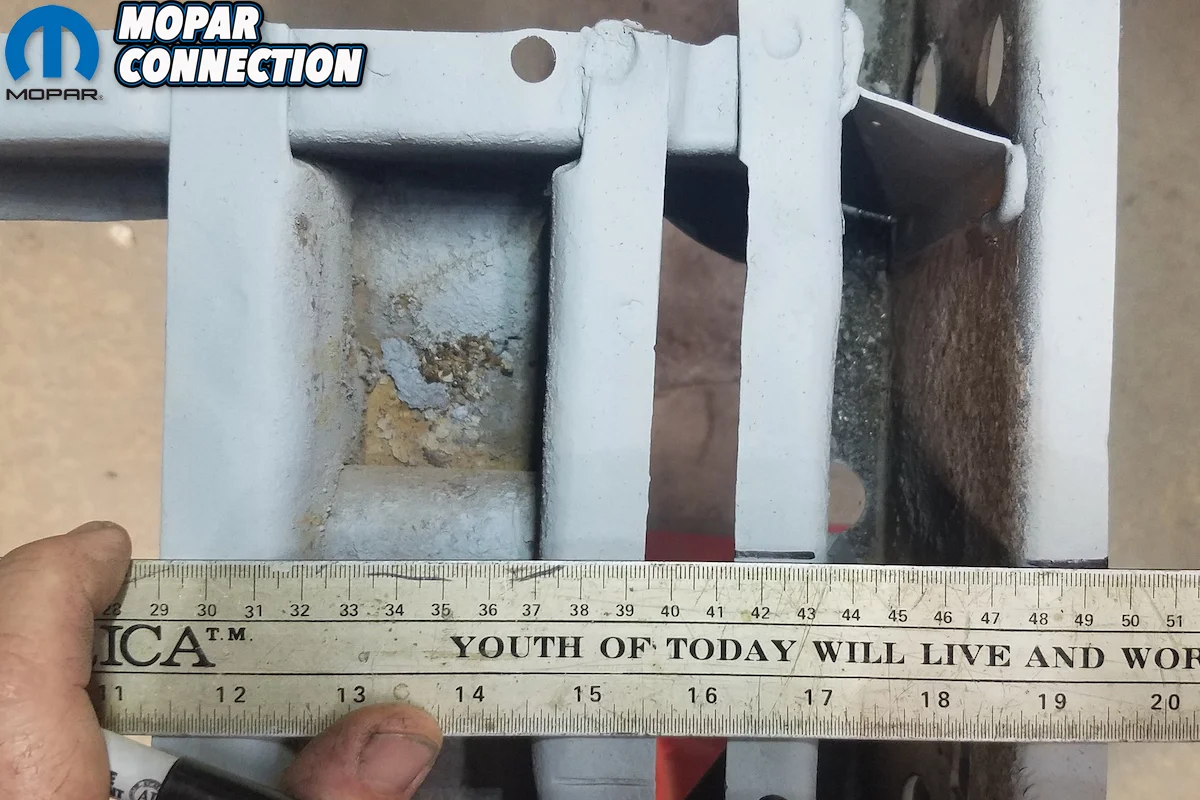

Prior to doing so, we needed to see what of the bumper brackets we could preserve. The pitting was bad, but the metal wasn’t corroded enough that it couldn’t take a weld. With the reinforcement bracket plates removed, we also could patch up the ends of the frame rails, repair broken flanges and replace what we could.

The steps taken in this article here aren’t terribly transformative in the visual sense. Yet, they are crucial to the overall structural integrity of the car. If David’s measurements are off in the slightest, the entire geometry of the car can be skewed.

Each step required several measurements from a variety of angles to ensure that the Super Bee remain square. Without the aid of a frame table or jig, this challenge was made doubly crucial. Once the rear frame rails are properly tethered could we begin installing the one-piece trunk pan.

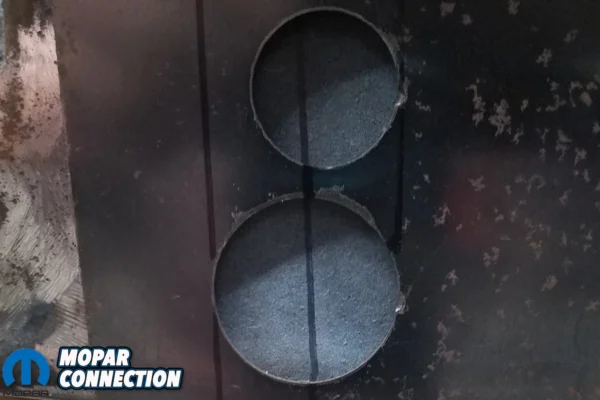

Since we’re doing so without the heavy industrial spot welders used by the factory or restoration outfits like the AMD Installation Center, our process was drilling out and fill-welding each replacement spotweld, and equally tedious task. Yet, when complete, the replaced trunk pan, side skirt/trunk extensions and rear cross member will look impressively close to factory-correct without having the benefit of half of the tools used by Chrysler.

Although a less skilled technician could perform the same task when equipped with said tools, the results would be nary indistinguishable – a testament to David Chamberlain’s talent when it comes to this level of restoration.

In this photo collection you’ll also find the preliminary steps taken in relocating the rear leaf spring perches in preparation for our USCT Motorsports mini-tub installation; the entire installation will appear in a later article as the steps in deepening our wheel wells, which also requires complete replacement, are extensive as well.

Finally, as David noted, “Tolerances up to 1/2-inch was passable back then. (No, really.) All of our tolerances are 1/8th-inch, well within spec.” This means that once completed, our ’70 Super Bee will be (conceivably) tighter, more square and better aligned than how it came from the factory. And with the addition of the USCT Stage III chassis stiffening kit, all the more stronger.

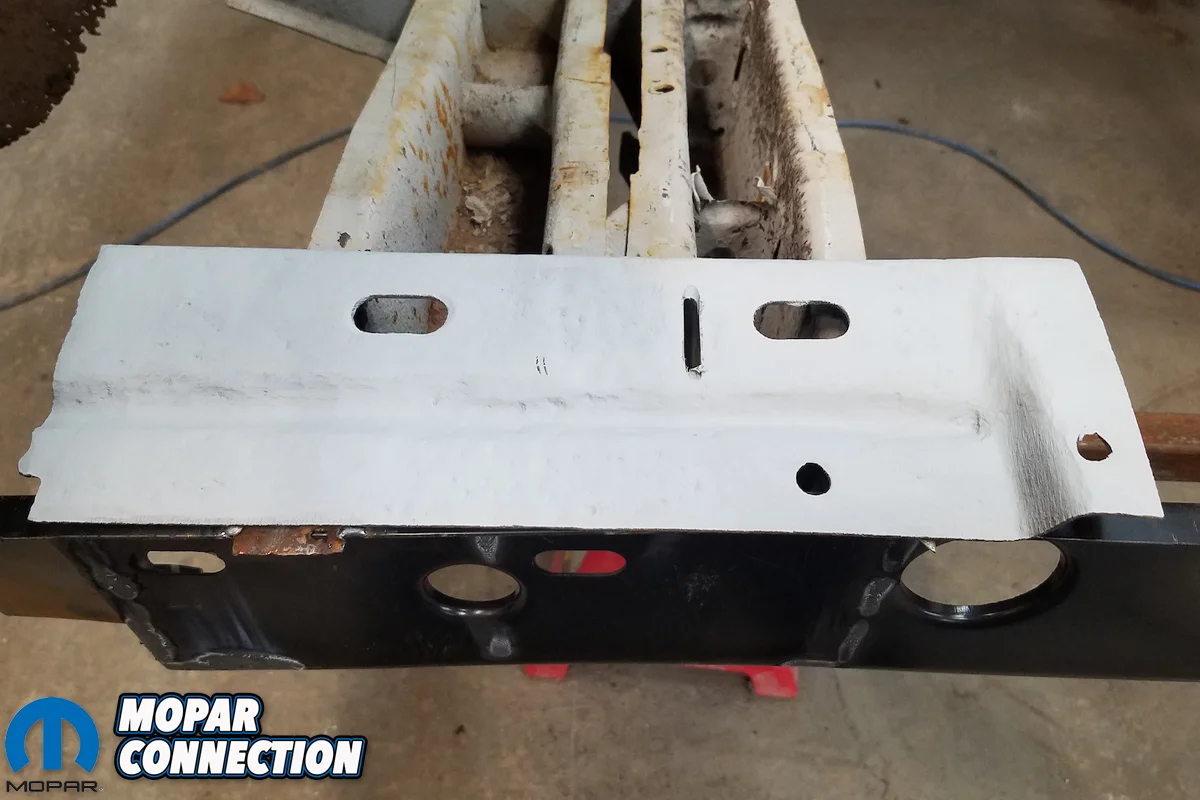

Above: Here we have cleaned up the frame rail surfaces, flatted and trued the perch rails for pan.

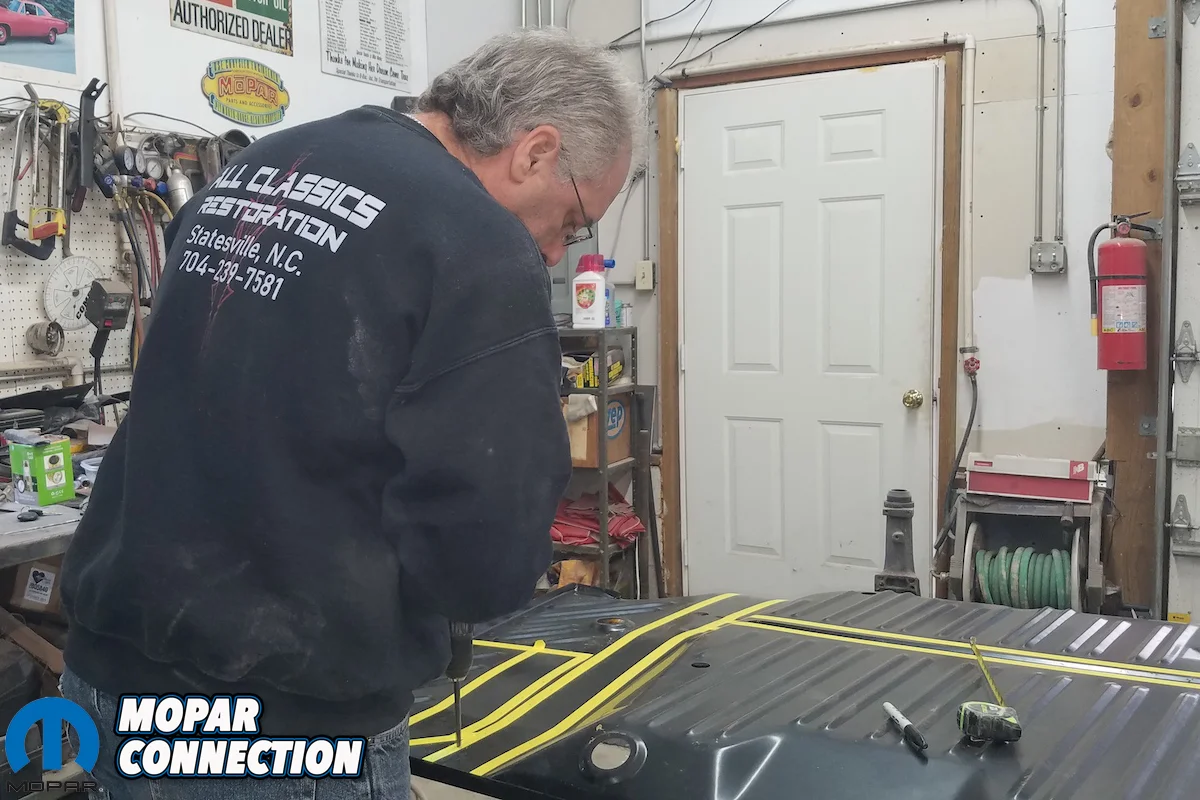

Above: Now we lay the pan back in the car, centered up where it needs to be, go on the bottom side and mark all the frame rails on the bottom of the pan (using either a Sharpie or scribe).

Above: The process of marking all of the holes is just as tedious as drilling them out.

Above: And trust us, there’s a LOT of drilling required.

Above: Here is a good opportunity to put our spring relocators in. Find centerline off of the original bushing sleeve and transfer it to the main frame rail.

Above: Using the U-plate from USCT, we find where the hole centerlines and mark the frame rail – using just the bottom hole to drill for new bushing location.

Above: Finally, the trunk, the rear cross member and trunk extensions are permanently installed in the ZomBEE. It’s is major first step in rebuilding the rotted out metal in our ’70 Super Bee. Next, we’ll tackle replacing – and widening – the rear wheel wells and finishing up the USCT Motorsports minitub kit.

Check out the full article at: Mopar Connection Magazine

Related Articles

ALL NEW TRIM for your Mopar A-Body

Jan 3, 2025 by DANK

Tech Articles

Making an A-body Whole Again with Hard to Find Metal from AMD

Aug 29, 2024 by DANK

Tech Articles